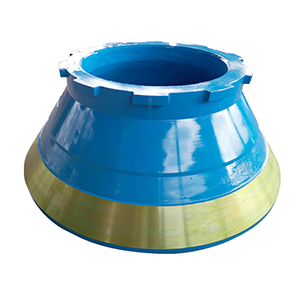

Mantle and bowl liner are the main wearing parts for cone crusher. Toughing can manufacture numerous models of concave and mantles for cone crusher. For the material of concave, TOUGHING use the Hadifield-steel , like Mn13Cr2,Mn18Cr2,Mn22Cr2, to ensure the wear resistance. Our cone parts are widely used on mining, constrution, chemical, cement and metallurgical indusery. After the modification treatment, combining with the special processing techniques, concave have a service life 10%-15% longer than those made of traditional materials.

Crusher Spares stock and supply an extensive range of aftermarket manganese cone crusher liners to suit the majority of the different makes and models of cone and gyratory crushers in operation around the globe.

All liners supplied by crusher spares are manufactured and machined to the highest quality standard and are all covered by our full guarantee for correct fitment and superior performance.

Case studies and customer reports comparing our wear liners to other suppliers have displayed up to a 50% increase in wear life across various applications using the identical profile design,

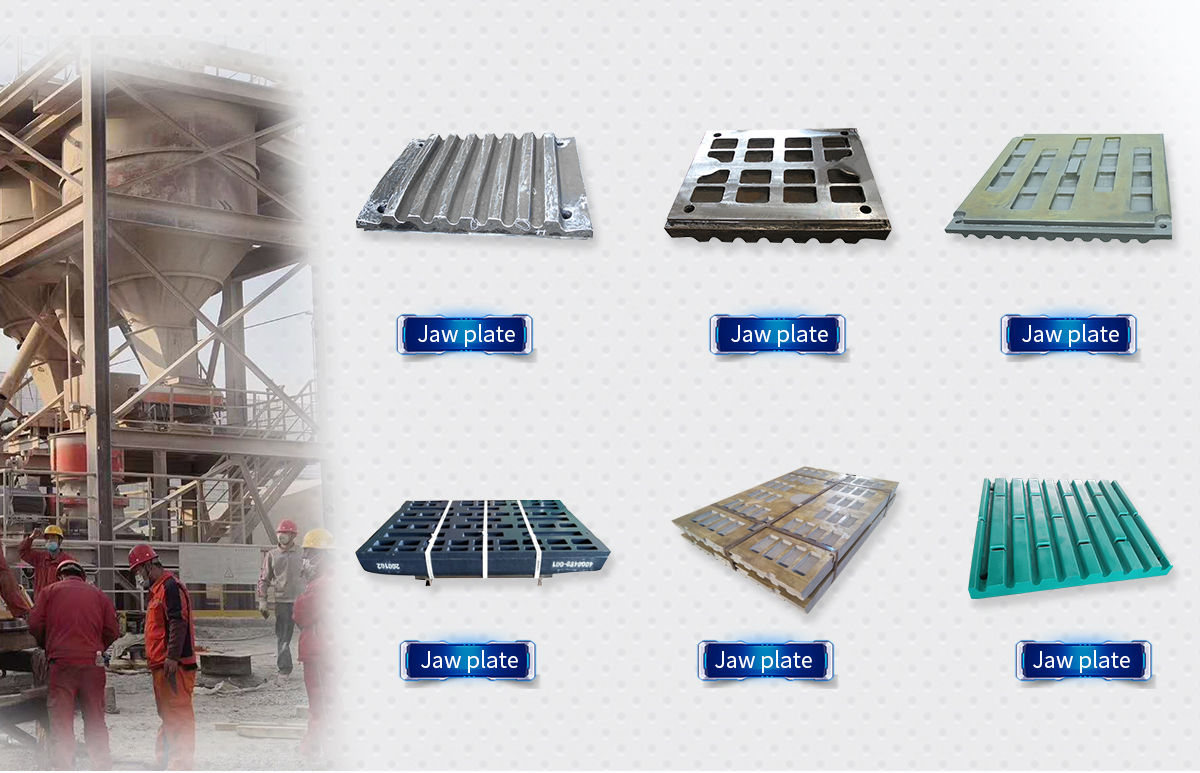

Our technical sales team, product engineers and pattern makers work closely together alongside our customers to develop and modify heavy duty jaw, cone and gyratory liner designs to further increase wear life, some of these modified designs have increased wear life in excess of 300% over standard design liners.

Categories: Bowl Liner, Cone Crusher Wear Spare Parts